Standardized Parts

Overview

Our commitment to standardized parts is fundamental to our AEPL excellence. We are proudly accredited with both the Qualified Manufacturer List (QML) and the Qualified Parts List (QPL), demonstrating our adherence to the highest industry standards. These accreditations reflect our dedication to producing components that ensure superior performance and reliability. Our portfolio includes a diverse range of multi-material O-rings and clamps with integrated materials, all meticulously manufactured to meet stringent specifications. By maintaining these rigorous standards, we deliver parts that provide exceptional safety, durability, and precision. This focus on standardized manufacturing reinforces our role in advancing aerospace technology and supporting successful, high-performance aerospace projects.

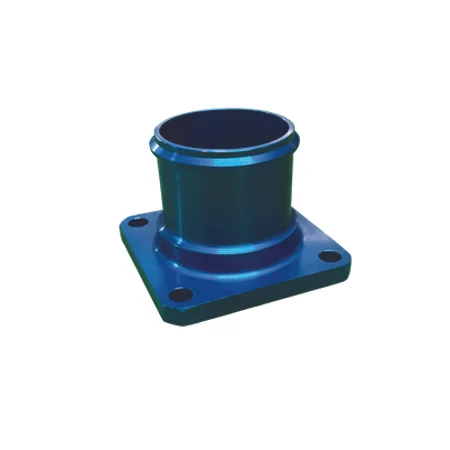

QML fittings

Fluid Distribution System – At AEPL, we are honored to be prominently listed on the Qualified Manufacturer List (QML), a mark of our dedication to top-tier aerospace manufacturing. We excel in producing highly intricate components, demonstrating our expertise in meeting the most stringent industry standards. Our inclusion on the QML highlights our adherence to rigorous quality controls, extensive testing protocols, and industry-leading accreditations. This prestigious designation not only underscores our capability to manage complex and demanding projects but also reaffirms our commitment to delivering reliable, superior products that meet the exacting requirements of the aerospace sector. We take pride in consistently exceeding industry expectations through excellence in manufacturing and quality assurance.

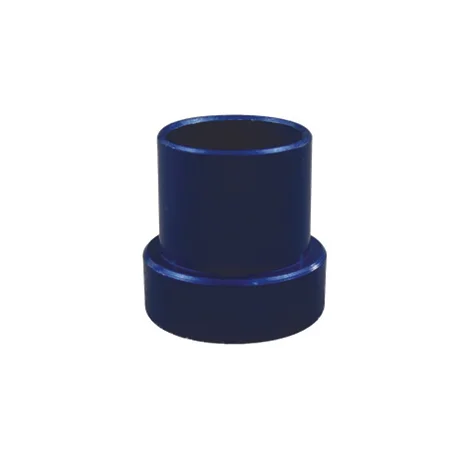

QPL fittings

AEPL is honored to be listed on the Qualified Products List (QPL), a critical designation for ensuring the integrity and performance of components in aerospace applications. The QPL status is awarded to products that have undergone rigorous testing and validation processes, confirming their compliance with stringent industry standards and specifications. This designation underscores our capability to produce components that meet precise engineering requirements and demonstrate reliable performance under extreme conditions. Our inclusion on the QPL signifies adherence to exacting quality control measures and rigorous evaluation protocols, assuring that our products are scientifically validated for use in advanced aerospace systems. We are dedicated to upholding these standards through continuous improvement and rigorous testing methodologies.

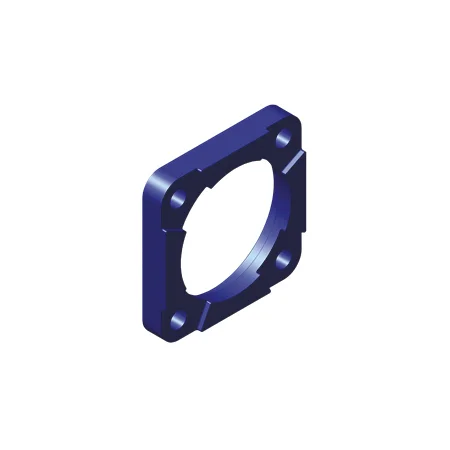

Clamps

At AEPL, we specialize in the precision manufacturing of Aerospace Standard Clamps, integrating diverse materials such as metals, rubbers, and composites within a single advanced facility. This multifaceted capability allows for streamlined production processes, optimizing both efficiency and product integrity. Our comprehensive in-house operations ensure meticulous control over all elements of clamp fabrication, reducing the need for external collaboration and enhancing the consistency of our outcomes. Supported by a suite of industry accreditations, we adhere to stringent aerospace standards, underscoring our commitment to producing components with exacting precision and reliability. This holistic approach not only simplifies supply chain complexities but also fortifies our position as a leader in aerospace component manufacturing.

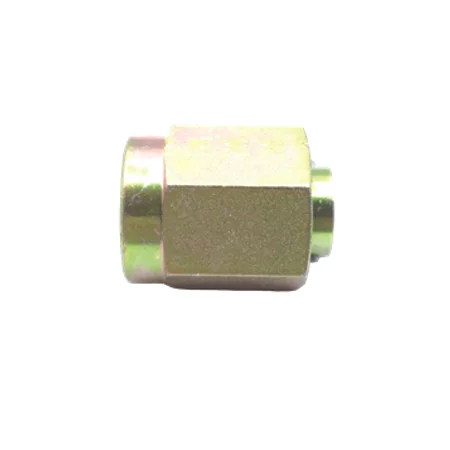

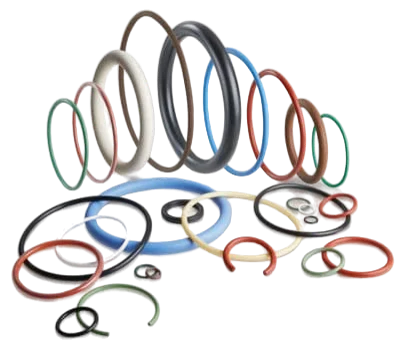

O-Rings

At AEPL, we are renowned for our world-class rubber material production capabilities, specializing in the advanced fabrication of O-rings. Our facility offers an extensive range of high-performance materials, including silicone, EPDM (ethylene propylene diene monomer), and Viton (fluorocarbon elastomer), among others. We utilize these materials’ unique properties—such as silicone’s excellent temperature stability, EPDM’s superior resistance to weathering and chemicals, and Viton’s exceptional chemical and high-temperature resistance—to meet specific customer requirements. Leveraging cutting-edge technology, we produce O-rings with precision, accommodating a variety of specifications to ensure optimal performance and reliability in aerospace applications. This capacity for customization, combined with our rigorous quality control standards, enables us to deliver O-rings that meet the highest industry benchmarks for durability and functionality. Our commitment to excellence in material science and engineering ensures that every O-ring we produce is tailored to the exact needs of our clients.